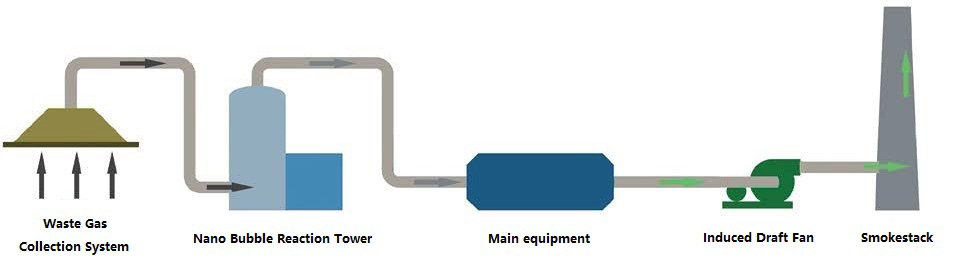

Working Principle

"Nanobubbles" are micron-sized water bubbles that make the atomic groups of water molecules smaller. The oxygen in the nanobubbles is easily dissolved in the gaps of the atomic groups. At the same time, the oxygen molecules break the interface of the water and make the ultrafine bubbles easier to dissolve. Into the water; the water molecules are always in "Brownian motion", and they constantly carry out irregular collisions. At the same time, when a large number of nano-bubbles are dissolved and ruptured in water, the instantaneous high temperature is about 5500 degrees Celsius, and when ruptured, an ultrasonic wave of about 400 kilometers per hour is generated and a large amount of oxygen anions are generated.

Technical characteristics

The process technology is completely different from the traditional domestic exhaust gas treatment scheme, with almost no secondary pollution, low resource consumption, low greenhouse effect, stable and reliable facility operation, extremely low failure rate, easy maintenance, and low operating costs.

The waste material derived from the process is simple to handle and there is no secondary pollution problem.

Can handle a variety of organic waste gas. [Ethyl acetate, cyclooctenone, NMP, DMAC, ammonia, trimethylamine, hydrogen sulfide, methyl sulfide, methyl mercaptan, methyl sulfide, dimethyl disulfide, carbon disulfide and styrene, sulfides H2S, VOCs, benzene Chain structure of benzene, toluene, and xylene]

The equipment has an outdoor types and indoor types. Outdoor type can effectively prevent wind, rain, frost, and rust.

In the operation of the equipment, no neutralizers, covering agents and other chemicals are used, and the only substrate used is water.

he main structure of the equipment is made of stainless steel and has a long service life. The equipment is easy to move and there is almost no material loss.