Main product introduction:

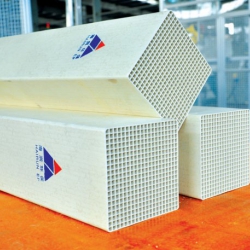

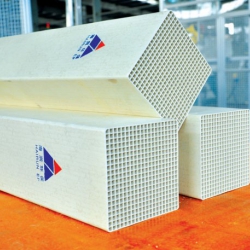

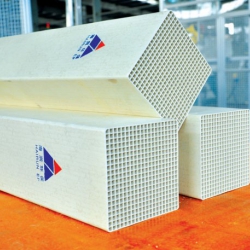

Shandong Hairun Environmental Protection Technology Co., Ltd. is mainly engaged in the production, sales and research and development of cellular SCR denitration catalysts. The catalyst product is integrally extruded, and the whole body is active, and even if the surface is worn, the catalytic activity inside is unchanged. The company's production technology for denitration catalysts imported from Germany, its complete production line production equipment are also imported from Germany.

The products are mainly divided into 3 series:

Classic V-Ti-W series denitration catalyst

Rare earth modified V-Ti-W series denitration catalyst

New environmentally friendly (vanadium-free) series of denitration catalysts

Product basic specifications:

Cross-sectional dimension: 150 × 150mm;

Length 300-1500mm;

The number of holes is 14 holes - 55 holes;

The inner wall is 0.3mm-1.3mm thick;

Features:

Using a full set of imported German technology and equipment, on the basis of the cited technology, digestion and absorption innovation, developed three series of denitration catalysts, high denitration performance at low temperature and high temperature.

It is widely used in low-dust and high-nitrogen flue gas conditions such as coal-fired power plants, chemical plants, glass factories, nitric acid plants, and ships.

Using a unique extrusion process, the prepared thin-walled catalyst effectively increases the porosity, reduces the drag drop, and reduces the power consumption and cost of the induced draft fan.

The modular design of the catalyst meets international standards and can replace the catalysts produced by different manufacturers.

Excellent performance:

High denitration efficiency ≥90% (modified denitration catalyst ≥92%); wide temperature range (250°C-450°C); SO2/SO3 conversion rate <1%; chemical life ≥24000h (according to customer requirements); mechanical life ≥ 80000h; high mechanical strength, wear resistance, suitable for low dust and high dust environment.