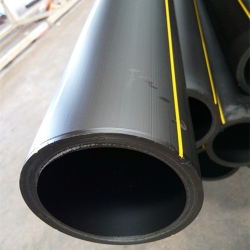

PE gas pipe definition

The polyethylene resin is used as the main raw material, and the extruded polyethylene pipe is extruded into a gas, which is referred to as a PE gas pipe. What color is PE gas pipe?

The color of the tube is yellow or black, and the black tube must have a bold yellow strip. What are the product specifications for PE gas pipes?

Standard size ratio SDR17.6 φ20~φ630 0.2MPa

Standard size ratio SDR11 φ20~φ630 0.4Mpa

Why is the SDR11 series suitable for the delivery of artificial gas and liquefied petroleum gas?

According to ISO 4437:1988 (E) A1: “If the liquid hydrocarbon (condensate, odorant or aromatic hydrocarbon) is to be contacted during the entire use of the pipe, the SDR11 (S5) series of pipes are recommended for a 50-year life. China's artificial gas and liquefied petroleum gas generally contain liquid hydrocarbons, so SDR11 is stipulated for the transportation of natural gas, artificial gas and liquefied petroleum gas.

What is the maximum allowable working pressure for the two series of pipes?

At 20 ° C, the maximum allowable working pressure of the SDR11 series is 0.4 MPa, and the maximum allowable working pressure of the SDR17.6 series is 0.2 MPa.

What are the advantages of PE gas pipes?

1) High strength, excellent stress crack resistance and good creep resistance;

2) Good toughness and flexibility, strong adaptability to unevenness and dislocation of the foundation, and resistance to harsh environments such as earthquakes and typhoons;

3) has good weather resistance (including UV resistance) and long-term thermal stability;

4) Corrosion resistant, long service life, suitable for conveying natural gas, liquefied petroleum gas and gas;

5) The inner wall is smooth, the circulation capacity is large, the gas flow rate can reach 20m/s, and the running cost is saved;

6) Good wear resistance and wear resistance;

7) Good anti-low temperature impact performance, safe use in the temperature range of -20-40 degrees, and winter construction is not affected;

8) The hot melt (or electrofusion) connection is convenient and reliable, and the construction and maintenance are simple (the air can be stopped without stopping);

9) Fully suitable for traditional excavation construction methods and new trenchless technologies such as pipe jacking, directional drilling, liners, split pipes, and submerged underwater;

10) Polyethylene raw materials contain only two elements of carbon and hydrogen, which are environmentally friendly and environmentally friendly.

Product advantages: Advanced equipment and processes use advanced imported equipment, excellent product technology to ensure product quality. Factory direct supply, price concessions using advanced imported equipment, excellent product technology to ensure product quality. Five-star service, worry-free use of advanced imported equipment, excellent product technology to ensure product quality.