Ion exchange systems are used widely across a variety of industries for water softening, purification, and separation purposes. Ion exchange is a treatment process where dissolved ion matter is replaced by their contrary ion substances.

Ion exchange columns

Ion exchange Spherical units

Ion exchange separate column

![]()

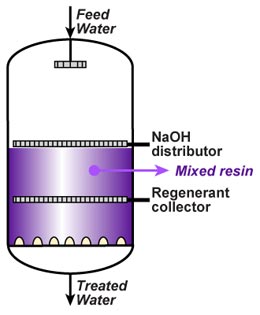

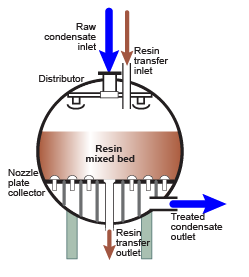

A well-designed IX system conforms to the conditions of a specific application in both physical design specifications and in the chosen IX resin material. Common components of a basic IX vessel include:

IX resin

Inlet distribution system

Regenerated distribution system

Retention elements

PLC, control valves and piping

Ion exchange resin must be strictly selected base on the purpose of usage. Commonly, it can be divided into two main categories, cationic resin, an anionic resin.

Cationic resins

Cationic exchangers can be classified as either strong acid cationic (SAC) resins or weak acid cationic (WAC) resins, both of which are extensively used for demineralization. SAC resins are also commonly used for softening, while WAC resins are used for de-alkalization applications. Contaminants removed by cationic resins typically include:

Calcium (Ca2+)/Chromium (Cr3+ and Cr6+)/Iron (Fe3+)/Magnesium (Mg2+)/Manganese (Mn2+)/Radium (Ra2+)/Sodium (Na+)/Strontium (Sr2+)

Anionic resins

Anion exchangers can be classified as either strong base anion (SBA) resins or weak base anion (WBA) resins. SBA resins are frequently used for demineralization, while WBA resins are often used for acid absorption. Contaminants removed by

anion resins typically include:

Arsenic/Carbonates (CO3)/Chlorides (Cl–)/Cyanide (CN–)/Fluoride/Nitrates (NO3)/Per chlorate (ClO4-)/Perfluorooctane sulfonate anion (PFOS)/Perfluorooctanoic acid (PFOA)/Silica (SiO2)/Sulfates (SO4)/Uranium