A member having a certain shape and capable of withstanding a load is called a structural member. In automotive bodies, many structural members are attached to the joints of the body structure and joined to other members to form a high-strength frame that is resistant to deformation. Such structural members typically have features such as large size, thin walls, and complex structures. Most of the automotive structural parts used iron or steel materials. According to the requirements of lightweight vehicles, these casting materials are transforming into lightweight aluminum alloys.

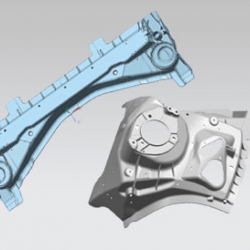

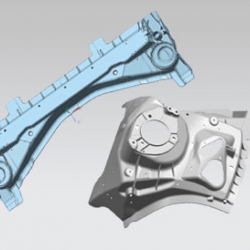

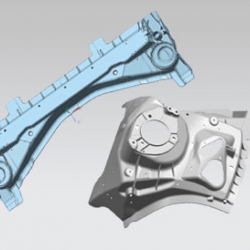

The aluminum alloy structural parts produced by Shanghai Pierboge Nonferrous Parts Co., Ltd. are designed by the world-leading Swiss Buhler large-scale high-pressure casting machine, which is designed as a fully automatic, fully enclosed and efficient linkage die casting island production mode. The products cover high-strength suspension towers, shock absorber brackets, long-bearing heavy beams and other structural parts. Developed and applied advanced die-casting technology such as vacuum die-casting and extrusion technology, and developed a heat treatment process suitable for die-cast structural parts. Product testing methods include spectrometer, X-ray flaw detector, GOM blue light scanning, and three coordinates. It is the first company in China to realize mass production of structural parts. At present, the technology and quality level of structural parts are first-class in the country and the world is leading.

Shanghai Pierboge Nonferrous Parts Co., Ltd. (KPSNC) was established on April 1, 2001, and was jointly invested by SAIC Motors owned by SAIC Group and Rheinmetall Automotive of Germany.

The company is a high-tech enterprise integrating high-pressure casting, low-pressure casting, gravity casting, machining and mold making. It mainly produces aluminum alloy cylinders, cylinder heads, structural parts, gearbox housings, chassis parts, new energy auto parts, etc. The products are supplied to SAIC Volkswagen, SAIC-GM, SAIC Motor, FAW-Volkswagen, JAC, Shenlong, Mercedes-Benz, BMW, Audi, Volvo and other major domestic and international automobile companies. They are well-known production bases and supply of automotive aluminum alloy parts at home and abroad. Business.

The company has a complete quality system, passed the ISO/TS 16949 quality management system and ISO14001 environmental management system certification, and actively promoted the SAP management process and KPS lean management system. So far, a complete and mature production process and quality control system have been established. The company has advanced production, research and development, testing equipment and experienced team to meet the needs of customers in a sincere and cooperative manner.

Companies adhering to the "casting quality" concept, "first is always our goal" the spirit of hard work, accelerate innovation and transformation, upgrade development, and actively promote the globalization of development strategy, to enter the forefront of the global non-ferrous foundry industry and struggle.