Product Category: Gear Reducer

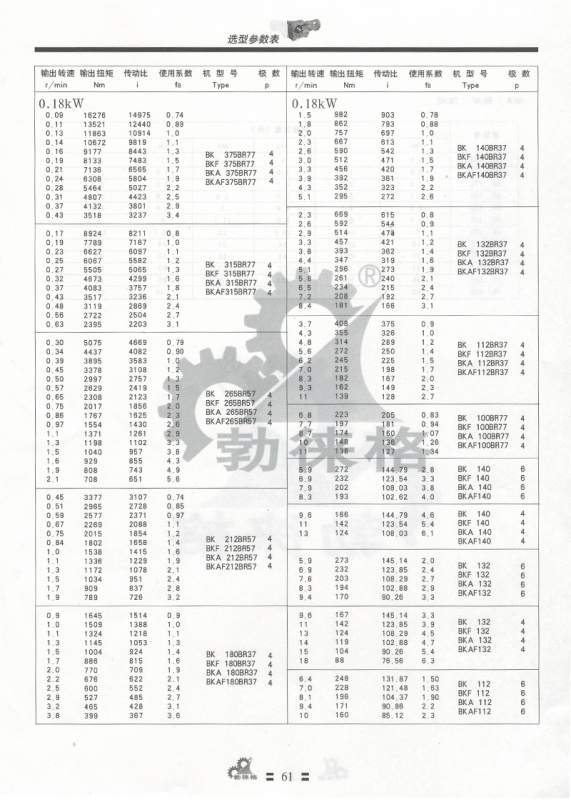

Product Description: Space saving, reliable and durable, with high overload capacity, power up to 200KW, low energy consumption, superior performance, deceleration efficiency up to 95%, low vibration, low noise, rigid cast iron box, high frequency heat treatment of gear surface After precision machining, it forms a helical gear and a bevel gear.

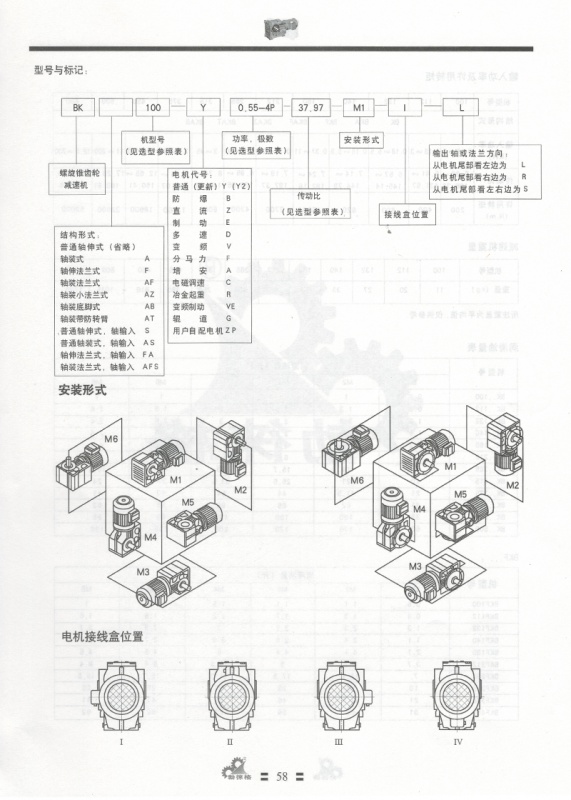

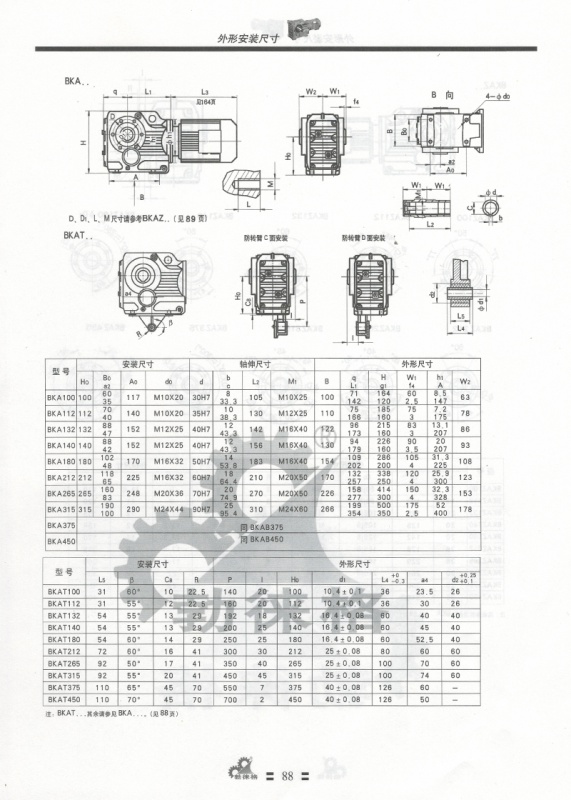

Installation form: vertical

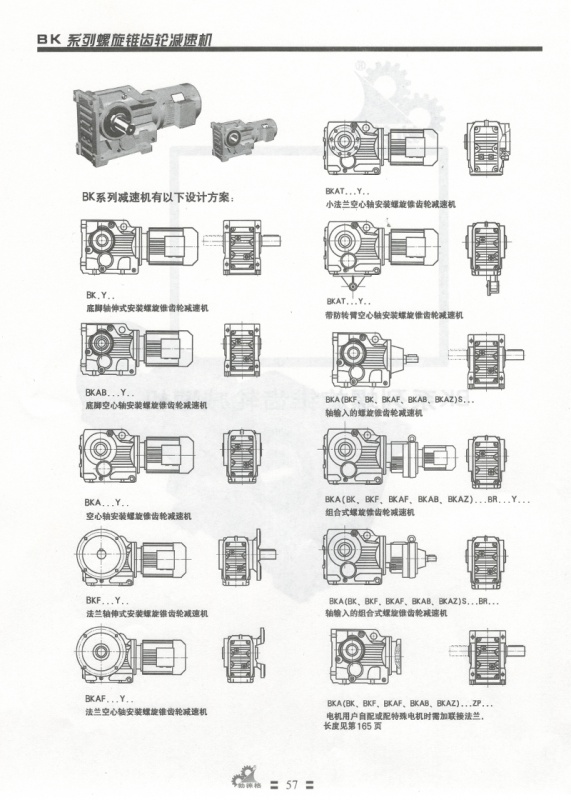

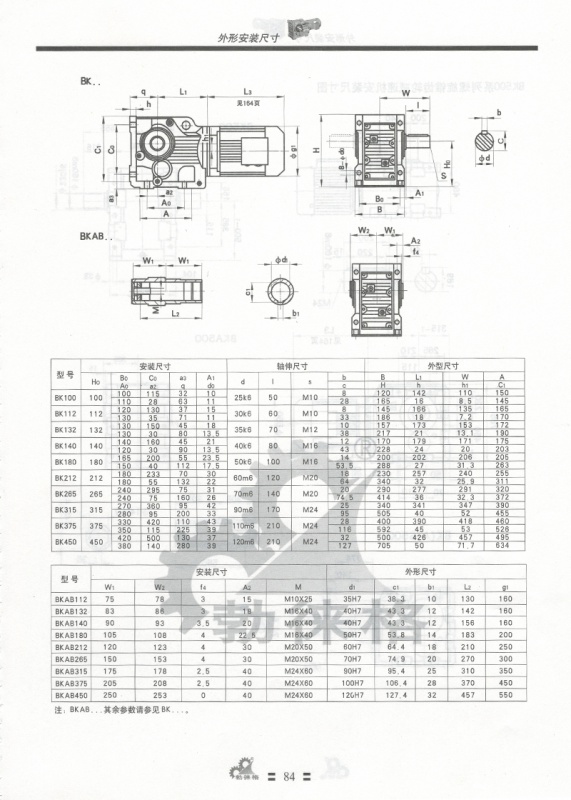

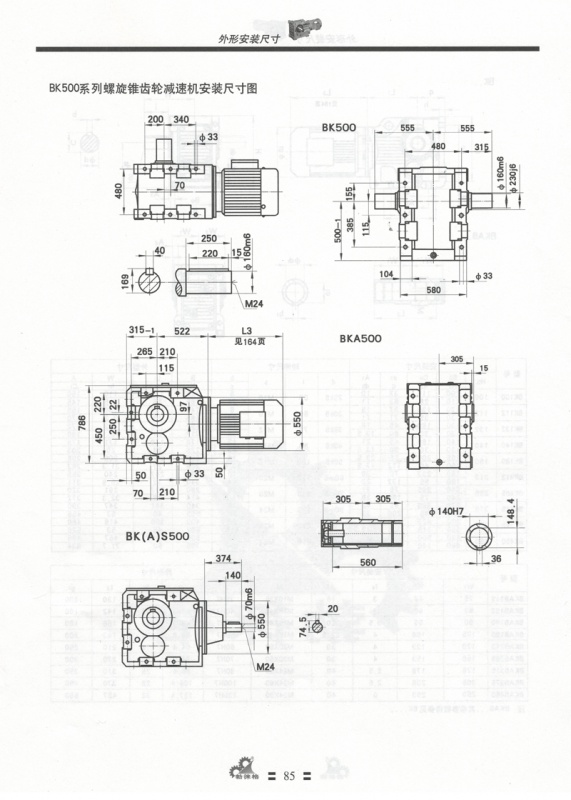

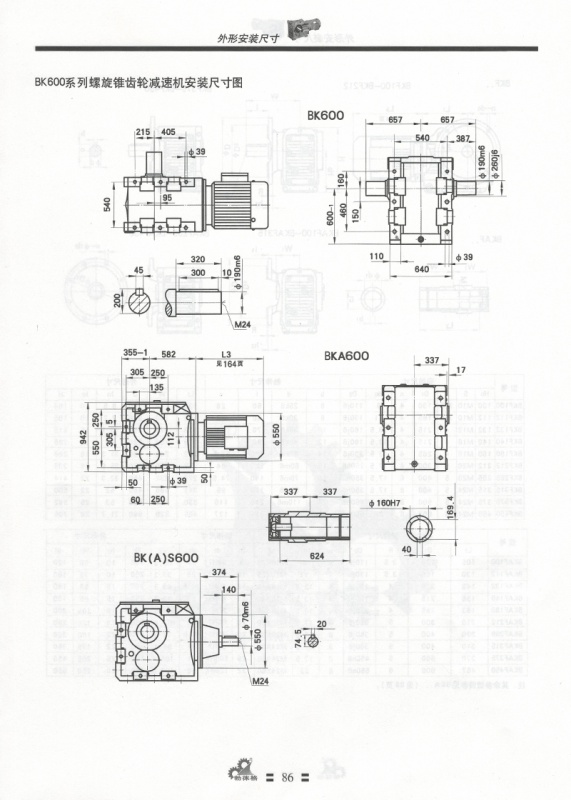

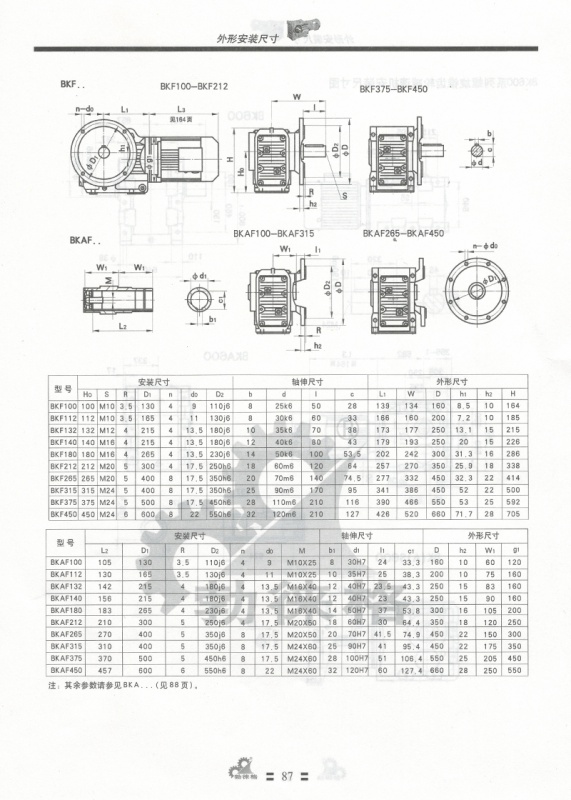

Structural form: K-shaft extension type, foot mounting; KA-shaft mounting type KF-shaft extension type, flange mounting; KAF-shaft mounted type, flange mounting KS- indicates shaft input

Zibo Bolaige Gear Motor Co., Ltd. is a science and technology enterprise specializing in the development, production and sales of high precision hardened gear reducer motors. Leading products YCJ, U, BR, BK, BF, BS and other series of hardened gear reducer motors, can be widely used in cotton spinning, chemical fiber, light industry, metallurgy, lifting, transportation, environmental protection, three-dimensional parking, mining, packaging, Mechanical transmission fields such as petrochemicals, road and bridge terminals.

The company is located in Boshan District, Zibo City, which is a national production base for reducing gears. It has beautiful scenery and convenient transportation. It is only 400 meters away from the entrance of Bolai Expressway.

The company has processing and testing equipment such as machining center, Swiss Les luxury worm wheel grinding machine and gear comprehensive detector. The gears are made of low-carbon alloy steel, which are subjected to forging, normalizing, carburizing, grinding and other processes, and the precision can reach ISO1328 standard 6.