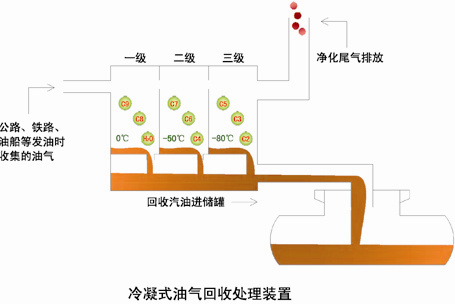

Process principle

The condensing oil and gas recovery technology uses the refrigeration technology to replace the heat of the oil and gas, and realize the direct conversion of the oil and gas components from the gas phase to the liquid phase. The condensation method is a method in which the vapor pressure difference of hydrocarbon substances at different temperatures is utilized, and the vapor pressure of some hydrocarbons in the oil and gas is supersaturated by cooling, and the supersaturated steam is condensed into a liquid state to recover oil and gas. Generally, the multi-stage continuous cooling method is adopted to reduce the temperature of the oil and gas, and it is agglomerated into liquid recovery. The minimum of the condensing device is determined according to the composition of the volatile gas, the required recovery rate, and the concentration limit of the organic compound in the exhaust gas finally discharged into the atmosphere. temperature.

· System features

1 Applicable to the site without absorbent;

2 The principle is simple and the process is mature;

3 directly visible recycling products;

4 installed power is higher;

5 operation energy consumption is high, subject to geographical restrictions.

Pailidi Environmental Engineering Co., Ltd. was founded in March 2008, is the research and transformation base of the Institute of Environmental Science, Fudan University, and with the Institute of High Energy Physics of the Chinese Academy of Sciences, Tsinghua University, Zhejiang University of Technology, Shandong University, Harbin University of Technology and other domestic scientific research institutions, specializing in industrial organic waste gas treatment of environmental protection new technology research, supporting equipment processing and atmosphere, sewage and other environmental engineering general contracting comprehensive high-tech enterprises.

At the same time, Palidis set up environmental protection academician workstation, Shandong plasma waste gas treatment research and development center, environmental protection enterprise of environmental engineering R & D center, there are a large number of innovative, practical technology born here. The company has registered capital of 50 million yuan, has environmental engineering design class B qualification (waste water, waste gas), environmental protection facilities operation and construction project contracting qualification and many other qualifications and perfect certification system.

As a technical enterprise in the industry of industrial odor gas management, perindi has always devoted a great deal of human, material and huge amount of capital to the atmosphere governance, sewage treatment and other environmental technologies with a high sense of social responsibility. At the beginning of the establishment of the company, the DDBD dual medium resistance of the DDBD was introduced for more than 10 years. When introduced, the technology was introduced in the completion stage of the laboratory principle prototype. After 8 years of engineering experiments and research of more than 400 different exhaust sources, the industrial application of DDBD has been realized. A lot of experience has been accumulated and a "low temperature plasma technology" has been created in the world. Palidis is known as the "low temperature plasma technology" industrial waste gas management brand. The technology is energy-saving, environmental protection, and has a wide range of applications. It has been rated as the national Torch Program, national environmental protection demonstration project, the first batch of key recommendation technologies of environmental protection in Shandong Province, and the national environmental protection technology project of National Encouragement and Development. The industrial application of the advanced technology and equipment is the first batch. The industrial application of this technology provides an effective way and technical basis for the odor purification, subverts the traditional technology. At the same time, combined with other waste gas treatment technology, more than 20 new technologies are developed, 60 items are applied for special profit, and the waste gas treatment project is completed by the end of 2015, and 40 works to complete the waste gas treatment project. The 408 item, production standard industrial waste gas treatment equipment 16 series, 150 varieties. In recent years, the company has developed a three-phase multi-medium catalytic oxidation technology, high performance liquid phase TRS purification system, mixed solvent dry cloud recovery and reuse technology, efficient water film separator, ultra clean emission and energy saving practical technology, greatly improved the company's market competitiveness. It has become a modern high-tech enterprise with R & D and design, project consultation, production and sales, and engineering general contracting.

In addition, the Palidis team has more than 10 years of experience in industrial sewage treatment. In the pharmaceutical, coking, printing, dyeing, landfill leachate treatment and other industries, the industrial wastewater treatment and municipal sewage treatment industry, has done a large number of high-quality projects. Has been the environmental protection management department and the user's consistent praise.