Working Principle of belt conveyor

It is composed with 2 rollers in both endpoints and the closed conveyor belt. Pulley which drive the conveyor is called the drive pulley; the other is called the return pulley. The drive pulley is driven through the reducer, while the belt is dragged by the friction with the drive pulley . The drive pulley is always installed in the delivery end so as to enlarge traction and in favor of dragging. Material is fed in the feeding end, and unloaded from the delivery end through the friction of the belt.

Now there are many other kinds of materials except the rubber belt, such as: PVC, PU, Teflon, Nylon and so on.

The belt conveyor is composed with rack, belt, belt roller, tension device, driver and so on. It can transport material in a conveyor line from the feeding position to the unloading position. It can transport not only the broken material but also the whole thing. Except the pure material conveying, the belt conveyor can match with certain technological process and form rhythmic production line.

Belt conveyor can be used in both horizontal and tilt transport, and it is widely used in the modern industrial enterprise, such as: mine underworkings, mine surface transportation system, open-air mining area and dressing plant, etc.

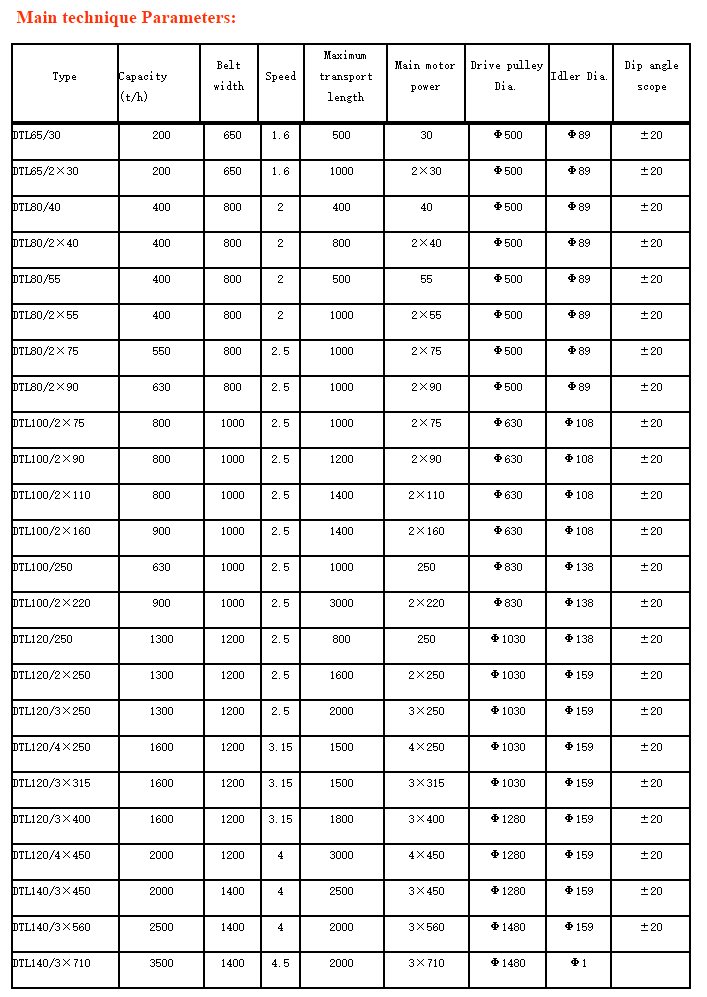

DTL Ground Fixed Type Belt Conveyor

This series of belt conveyer, can be widely use in the metallurgy, the coal, the transportation, the power, the building materials, the chemical, the light, the grain and the mechanical industries, the transportation bulk density is 500-2500kg/m3 for bulk material and other items, the suitable ambient temperature is – 10℃ to 40℃, when selects this series product, you need to use the special rubber conveyor belt and concurrently uses the corresponding protective measure in order to satisfy the heat-resisting, cold-resisting, anticorrosion, the explosion-proof, anti-flaming etc.