Mid(Low)-consistency cleaner

1. Application:

Low consistency cleaner used to remove the small heavy rejects from the pulp system and improve the final pulp quality. Protect the following instruments from wearing.

2. CEH structure characteristics and benefits:

a) The operating reliability of cleaner plants is always increased by lowering the stock consistencies in the lower cone area. In addition, back flushing allows operations of a cleaner with lower volumetric reject rates and lower rejects stock consistencies. It is thus possible to design the following stages considerably smaller than before. Consequently, the required number of cleaner stages is substantially reduced, providing large savings, both in the overall infrastructure required for operating a cleaner system, as well as in pumping energy.

b) Higher separation efficiencies for contaminants, which are difficult to remove, like dirt specks, have already been mentioned. Alternatively, the cleaners can be operated with higher inlet stock consistencies than before, while maintaining the previous efficiencies. Due to the dilution of the rejects, the stock consistency in the bottom cone area still remains lower than with conventional cleaners. With higher inlet stock consistencies, new arrangements are possible concerning fine cleaning and fine slotted screening systems in recycled paper stock preparation plants.

c) Finally, contaminant concentration can now be increased with continuous reject discharge in the final stage to such an extent as it was previously only possible with periodically rejecting final stages. Through minor changes to existing systems, considerable reductions in losses and thus a lot of savings have already been achieved.

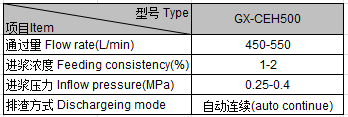

3. CEH Selection:

According to the pulping system raw material and capacity requirements to select the most appropriate instruments. (See our questionnaire) We have provided the best solution for you according to your inquiry, and trust that our proposal will meet your requirements.