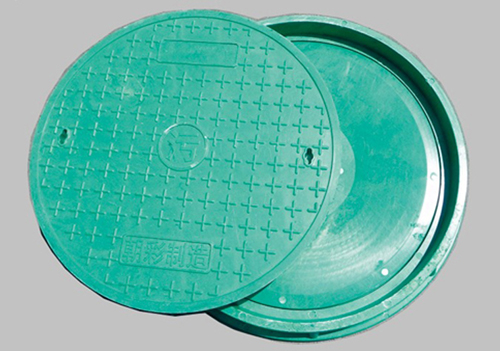

As a kind of inspection manhole cover, the composite manhole cover uses a polymer as a base material, and adds a reinforcing material, a filler, and the like, and the inspection manhole cover is formed by a certain process. The new national standard has increased the load requirements of the manhole cover and is in line with the internationally accepted EN124 standard. The standard will be implemented from February 1, 2010. A fiber-reinforced thermosetting composite material based on unsaturated polyester resin, also known as agglomerate molding compound (DMC), is made by press molding technology and is a new type of environmentally friendly cover plate. The composite manhole cover adopts high temperature and high pressure one-time compression molding technology, which has high polymerization degree, high density, good impact resistance and tensile strength, and has the advantages of wear resistance, corrosion resistance, no rust, no pollution and maintenance-free. The inside of the composite manhole cover is reinforced with mesh steel bars, and the key force parts are specially strengthened. When an inevitable external force impact occurs, the pressure can be quickly dispersed to ensure the safety of the people. Metal-free, stone-plastic manhole covers and concrete manhole cover steel skeletons are less than 1/10 of the total weight of the manhole cover. There is not much value for theft. And because the strength of the manhole cover is extremely high, it is extremely difficult to remove this small point of steel from the manhole cover. Performance characteristics 1. High strength: It has high strength against bending, bending and impact, and has toughness. After long-term use, the product will not be crushed and damaged, which can completely eliminate the "black hole" accident. 2, the appearance of beauty: the surface pattern is beautifully designed, the color is bright and adjustable, beautifying the urban environment. 3, easy to use, light weight: the weight of the product is only about one-third of the cast iron, easy to transport, installation, repair, greatly reducing the labor intensity. 4, no recycling value, natural anti-theft; according to customer needs and with a locking structure to achieve security in the well. 5. Strong weather resistance: The manhole cover can be used normally in the environment of -50℃ ~ +300℃through scientific formula, advanced technology and perfect technical equipment. 6, acid and alkali resistance, corrosion resistance, wear resistance, resistance to vehicle rolling, long service life. Prospects With the rapid development of urban and rural construction, the demand for manhole covers for new residential buildings and roads has increased dramatically. The cost of traditional cast iron manhole covers is high, and theft is serious. Pedestrians are injured and vehicles are damaged. It has been a problem. The problems of the construction departments. The composite manhole cover mainly uses unsaturated resin as the main chemical raw material, and composites a variety of materials. After molding, not only high strength, beautiful appearance, but also good electrical insulation performance, waterproof, aging resistance, acid and alkali resistance, high strength, Anti-impact, wear-resistant, not afraid of sun and rain, anti-static, anti-theft, etc., is an ideal substitute for cast iron manhole cover.