The gas generator can be widely used in combustible gas power generation of coal mine gas, biogas, natural gas, oilfield associated gas, biomass gas, landfill gas, coke oven gas, semi-coke gas, oil shale refinery gas, calcium carbide gas, etc., through the utilization of exhaust gas to achieve comprehensive and efficient use. Company main products are 300 series gas generator sets, 300 series refer to 6300, 8300, 9300 series medium speed gas generator set, speed is 500r/min, 600r/min and 750r/min, the power range of 100kW to 1500kW. After the successful operation of thousands of generator sets and more than 300 power stations, product performance has been testified, gas generator sets are featured by stable power output, low exhaust temperature, long annual running time, low maintenance and operation cost, safe and reliable.

Main Technical Features

Large displacement, low speed, large power reserve, stable & continuous power output, long maintenance cycle.

Non-turbocharged naturally aspirated with inter-cooler, strong adaptability to poor quality gas, low failure rate.

The gas intake system is equipped with an emergency cut-off solenoid valve, flame arrester, explosion-proof valve and multi-channel protection facilities with complete alarm protection, ensure safe operation.

Automatic control of air-fuel ratio, strong adaptability to gas fluctuation, stable power output, and low breaker open rate.

Inner mixing gas generator, gas, and air intake separately, mixing and combustion in the chamber to ensure the safe use of high hydrogen gas, no tempering blasting danger.

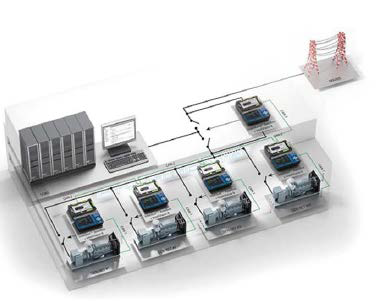

The international advanced COMAP control system is configured, with perfect parameter measurement, alarm protection and power management of the grid-connected and parallel operation.

Automatic control and centralized network monitoring can effectively reduce operating costs, improve power generation efficiency and ensure stable and safe operation.

Exhaust heat can be recycled producing steam or hot water, which can realize the efficient use of gas. High reliability, unit annual operating time is more than 7500 hours, overhaul about 60,000 hours.

High-end Genset With Fully Automatic Control Function

Unit parameter acquisition and record

Acquire unit parameters through the sensor or RS485 bus, including speed, oil pressure, oil temperature, water pressure, water

temperature, exhaust temperature, voltage, current, power, power factor, electric energy, mixer butterfly valve opening and so on. All collected parameters can achieve historical records and inquiries.

Alarm protection and event recording

The unit has a sound alarm protection, including over speed, low oil pressure, high oil temperature, high water temperature, high exhaust temperature, low exhaust temperature, over-voltage, under-voltage, over-current, and overload. Realizing all alarm protection events historical records and inquiries.

Communication network and HMI

Controller, touch screen and IPC communication using Ethernet. A single unit can simultaneously support

multiple touch screen, seamless integration, real-time, the same feeling of the remote and local operation.

A key start, automatic sequence control

Press the start button to start the Genset and parallel power generation, the entire process without human intervention, the control system automatically complete all the operations in sequence: pre-supply oil, start, no-load air, fuel ratio adjustment, idle speed, rated speed warm machine, synchronous parallel, automatic control of air-fuel ratio + automatic control of power + constant power factor control.

Fully automatic air-fuel ratio control

Automatic control of the air-fuel ratio accompanies the whole operation of the unit. Control algorithms have universal applicability for all types of gas.

Automatic load distribution of island operation

Multi-machine island operation or parallel operation mode, multiple units automatically and evenly share active power and reactive power; multi-machine grid-connected operation, the total power of all units change according to factory load change, not to send power to the power grid.