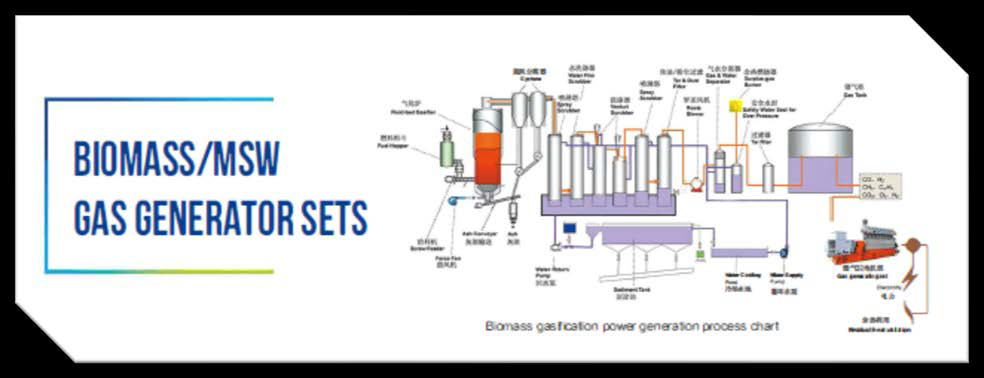

Gasification power generation technology use wood, straw, rice husk, MSW and other agricultural and forestry resources as raw materials, collected, crushed, briquettes, and burned under high temperature in the furnace to produce combustible biomass gas, gas first be cleaned to remove dust, tar and sulfur, then

delivered to internal combustion engine to invert to power, while exhaust heat from the engine can be used to produce hot water or steam, to achieve a comprehensive and efficient use of biomass energy. 300 series biomass gas generator is also suitable for garbage gasification power generation.

Application Field

Gas Requirement

Before operation, the gas should be treated to remove dust, tar and sulfur, dehydration and cooled to meet the following requirements:

Gas temperature ≤40°C Gas pressure 2.5-0kPa Pressure change rate≤1kPa/min

Calorific value≥4.0MJ/Nm3 Moisture content≤40g/Nm3, no free water Impurity content≤30mg/Nm3

Impurity size≤5μm H2S≤50mg/Nm3 Total sulfur content≤ 100mg/Nm3

NH3≤20mg/Nm3 Cl≤50mg/Nm3 H2≤50% 02≤1 Tar content≤50mg/Nm3

Technical Features

Genset power is high, the power range of 350kW to 600kW;

Non-turbocharged naturally aspirated, double tube gas intake system with high tar tolerance;

Intake valve kit is removable for easy maintenance;

External or internal mixing system can be selected according to hydrogen content;

Adapt to low calorific value gas with high hydrogen content;

High degree of automation, high safety, and low operating costs.

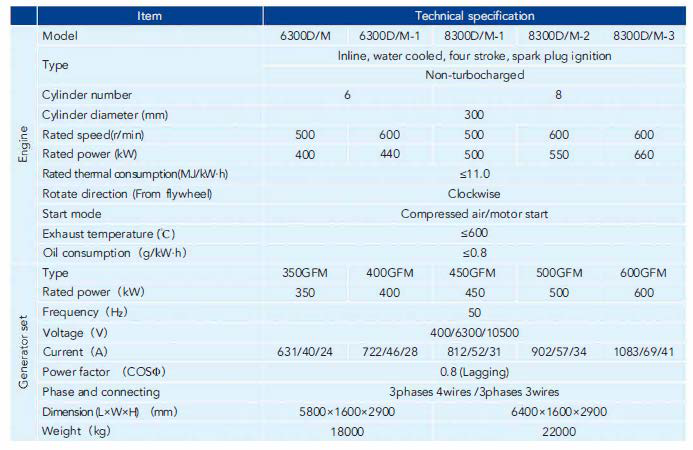

Technical Specification