The self-developed and produced self-propelled zirconia wear-resistant composite pipe of our company is the first in the industry, which overcomes the traditional method of only setting press and kiln roasting in China, and fully realizes the advanced manufacturing process of pipe and zirconia combined at one time. .

Process and performance

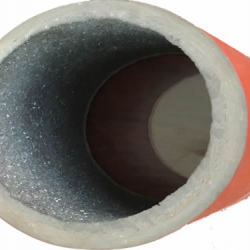

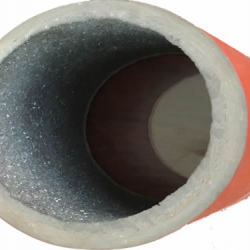

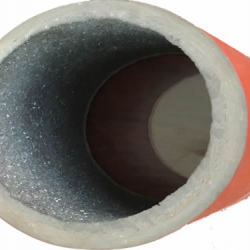

The self-propelled zirconia wear-resistant composite pipe is composed of a zirconia wear-resistant layer, a transition layer and a steel pipe from the inside to the outside. The manufacturing process adopts high-temperature centrifugal combustion technology to form a dense and smooth process in a molten state above 2700 ° C. Zirconium oxide wear layer.

Physical properties of self-propelled zirconia wear-resistant composite pipe

project material | Rockwell hardness(HRA) | Bending strength (MPa) | density(g/cm3) | Fracture toughness (MPa) |

Self-grown zirconia wear-resistant composite pipe | ≥85 | ≥1000 | 5.96 | 12-14 |

Features and uses

The unique manufacturing process determines the high hardness, high density and high wear resistance of the self-propelled zirconia wear-resistant composite pipe, which has the following characteristics:

1. Convenient and flexible installation: The product can meet the welding and cutting on site without flange connection. Alumina ceramic patch pipes can only be flanged, which greatly reduces the investment cost.

2. The inner liner of the steel pipe is firmly combined, seamless, and not easy to fall off: compared with the alumina ceramic patch pipe, the partial peeling phenomenon during use is solved due to poor adhesion.

3, non-sticky, non-blocking: and lining polyurethane pipeline, once the inner lining layer falls off a large area, it is easy to cause blockage of the pipeline, which will cause system shutdown.

The product can be widely used in coal, metallurgy, mining, electric power and other industries to transport grinding medium pipelines, such as: coal washing plant heavy medium coal preparation pipeline; steel plant blast furnace waste gas, water slag, sintering head, tail dust removal pipeline Mine beneficiation and filling pipelines; power plant boiler powder feeding elbows, ash slag pipelines, etc. It is the ideal medium conveying pipe under harsh environmental conditions.