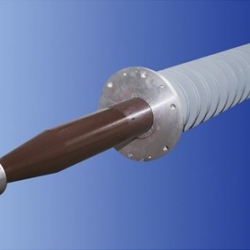

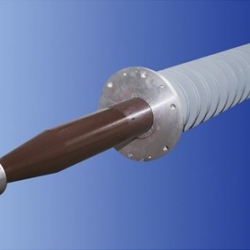

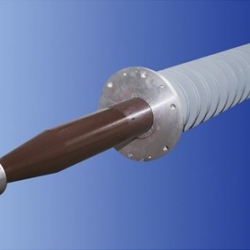

FRP capacitive transformer bushing is a new type of dry type transformer casing with our own intellectual property rights. It is an epoxy resin impregnated glass fiber winding system. The insulating layer is made by spiral wound. The capacitor screen is wrapped around a semiconductor conformal material, and the alternating winding interval between the insulating layer and the capacitive screen is set by high temperature solid. A pure solid capacitor core is made. According to the requirements of use and assembly, the shape and fit size are processed by mechanical processing. The connecting flange is directly glued to the insulating outer protection layer of the capacitor core, and the external insulation is injected directly on the surface of the capacitor core by the rubber climbing umbrella group injection molding process. The casing has a very high mechanism strength, simple structure, very few seal links, and no need for maintenance.

The product has the following characteristics:

A. the product has no oil, no porcelain, no gas solid solid, no filler, no leakage, good moisture resistance, no need for maintenance.

The B. design has large insulation margin and semiconductor capacitance screen, which maximizes the corona onset voltage and has no PD in operation.

C. flame retardant insulation material, no decomposition, electrical performance is stable, no danger of combustion and explosion.

D. compact structure, small size, light weight, easy to transport, can be installed at any angle.

E. glass fiber reinforced winding, optimized mechanical layer design, high bending strength, high mechanical strength, is also very reliable for heavy earthquake areas.

F. has excellent high and low temperature resistance. It has been used in electrostatic precipitator (+ 135 C) and superconducting cable connector (one end + 90 degrees centigrade, the other end 200 degrees centigrade).

G. silicone rubber composite coat has strong anti pollution flashover capability and is self-cleaning without cleaning. It can be used in heavy polluted areas.

H. has long service life and low long-term operation cost.

I. processing cycle is short, special design can be done according to user requirements.