Biological wastewater treatment processes are primarily designed for the removal of dissolved and suspended organic matter from wastewaters.

Biological wastewater treatment is also capable of removing other wastewater components, including suspended solids, nitrogen, phosphorus, heavy metals, and xenobiotics.

The Membrane Bioreactor or MBR is based on the conventional wastewater process, but the separation of

micro-organisms is performed by filtration with membranes.

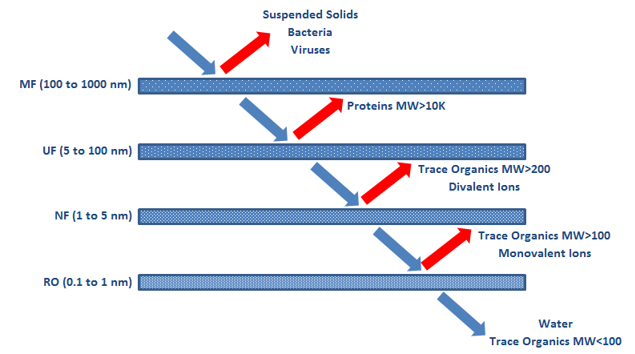

Membrane filtration has a major role in water and wastewater treatment, which is superior to conventional water

technologies with proven better performance and more efficient economics. The basic membrane processes are

microfiltration (MF), ultra-filtration (UF), nano-filtration (NF), reverse osmosis (RO). Separation ranges for those

membranes are as follows: 100 to 1000 nm for MF, 5 to 100 nm for UF, 1 to 5 nm for NF, and 0.1 to 1 nm for RO. For

more than the last 10 years, MBRs have emerged as an effective secondary treatment technology by using membranes in

the range of MF and UF.

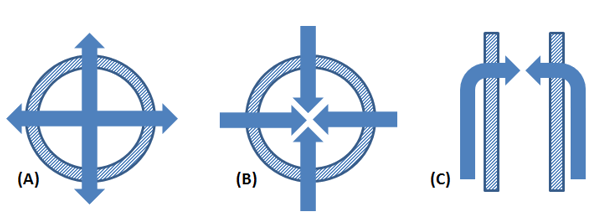

In general, MBRs have three distinct membrane configurations, have been applied to treat effluent in a number of

industrial sectors, like

Food and beverage − high in organic loading

Petroleum industry − exploration, refining and petrochemical sectors

Pharmaceutical industry – have active pharmaceutical ingredients (APIs)

Pulp and paper industry − high levels of suspended solids, COD and BOD

Textile industry effluent − re-biodegradability, toxicity, FOG content and color

Landfill leachate − a wide variety of dissolved and suspended organic and inorganic compounds

Ship effluents − legislative requirements and space restrictions.

Industrial versus municipal treatment

MBR membrane configurations, A) Hollow Fiber, B) Multitube, C) Flat Sheet